This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The Time Is Right to Focus on Developing New Battery Material Chemistries

An Opinion Article by Dr. Ganesh Skandan

A global push to establish a battery manufacturing infrastructure will provide avenues to implement new Advanced Materials. New battery material chemistries, along with innovative manufacturing methods, can lead to low-cost EV batteries with the desired performance and safety features. The involvement of stakeholders across the entire value chain, early in the materials development process, can reduce time to market… continue reading »

The Development of NEI’s Anti-Ice Coating Technology for the Aerospace Industry

A Case Study of NANOMYTE® SuperAi from Concept to Implementation

Ice formation on the leading edge of an aircraft is a common aviation danger, playing a key role in many catastrophic accidents that have killed people and destroyed aircrafts. A manufacturer of de-icing systems brought up the idea of combining an active de-icing system with a coating that easily sheds ice. The challenge presented to the engineers and scientists at NEI Corporation was to develop and demonstrate a coating that exhibits durable anti-ice performance and satisfactory wear and erosion resistance… continue reading »

Exploring the Capabilities of Electrospinning

Morphology & Applications of Electrospinning Nanofibers

Among the several methods to make nanofibers, electrospinning is deemed the most promising due to its ability to produce continuous nanofibers on a large scale and adjustable fiber structures from a variety of electrospinnable polymers. Here, we review the morphology of electrospun nanofibers and the various parameters and versatile techniques used to transform a wide range of polymers and ceramics into fiber structures. We also explore the growing number of applications where electrospinning is showing promising results in the environmental and biomedical fields, as well as energy storage. Continue reading »

Solid Electrolytes: Are we there yet?

Solid Electrolytes for Lithium-ion and Lithium-Sulfur Batteries: A Safer Solution

Lithium-ion batteries have provided a lightweight energy-storage solution that has enabled many of today’s high-tech devices – from smartphones to electric cars. Although these batteries are generally safe, fire and explosion concerns have caused the industry to seek solutions, such as replacing liquid components used in existing lithium-ion batteries with all solid materials. This would not only solve the safety issue, but would also provide several other significant advantages, such as greater energy storage ability, no dendrite formation, chemical and electrochemical stability over a wide voltage window, and exceptionally long cycle life… continue reading »

A New Perspective on Coatings and Surface Treatments

NEI Corporation’s Patented Technologies Provide a New Perspective on Coatings and Surface Treatments

Gains in productivity and efficiency are possible when a coating or surface treatment provides functionalities beyond the usual protective and aesthetic properties. This realization has sparked great interest in functional coatings in recent years for applications that traditionally have not used paints or coatings. While great strides have been made in academic circles to understand the different surface phenomena of these so called ‘smart coatings’, commercial products to date have met with limited success because they are not engineered to meet all of the functional performance requirements… continue reading »

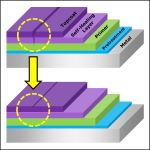

A New Approach To Using Self-healing Coatings

NEI’s Approach for Utilizing a Self-Healing Coating to Impart Enhanced Corrosion Protection to Metals

A traditional protective coating system on a metal substrate generally consists of a pretreatment, primer, and a topcoat. The base metal is pretreated and primed for enhanced adhesion and corrosion resistance. A topcoat is then applied on the primer. Many of the coatings in use today to inhibit corrosion are “passive” in nature, in that they provide only barrier protection and/or promote adhesion between the metal and overlaying paint. While these are important attributes, passive solutions do not… continue reading »

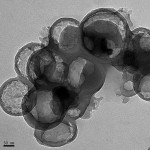

Case Studies in Designing New Nanoscale Materials

Core-shell Particles | Sulfide and Oxide Nanoparticles | Hollow Fibers

Core-Shell nanoparticles are composite particles where a core material is coated with a material of a different composition (shell), imparting unique functionalities that are otherwise unattainable for the individual materials. Such nanostructured particles have diverse applications. NEI Corporation has recently developed a patent pending, scalable process to produce core-shell nanoparticles. The process can be used to manufacture metallic and ceramic core-shell nanoparticles, such as metal / metal oxide and metal / metal boride core-shell nanoparticles. The versatility of the process allows core-shell nanoparticles to… continue reading »

Recent Advances in Self-Healing Fiber-Reinforced Composites

A New Nanotechnology Approach for Micro-crack Prevention and Impact Resistance in Self-healing Fiber-Reinforced Composites

Composites are rapidly becoming the material of choice for various applications. The more familiar carbon fiber composites are used where a lightweight structural material is required. Airplanes, such as the Boeing Dreamliner, utilize fiber composites for their high strength to weight ratio, which ultimately decreases fuel consumption. This also translates to the automotive industry; the lighter the car is, the more energy efficient it can be. Another example is sporting goods… continue reading »

Lithium Titanate Based Batteries for High Rate and High Cycle Life Applications

In general, the demand for smaller and lighter batteries has been growing drastically during the last decade. Conventional lead acid batteries have been in use since 1860 in stationary applications. Lead acid batteries are still widely used due to their low cost, matured state of development, and ruggedness compared to other battery technologies. However, lead acid batteries (both flooded and VRLA) are heavier and bulkier. They also do not cycle well to meet some of the demanding new application needs… continue reading »